ZFT participated in 2023 FILTECH

2023.2.14-16

The world's top event in the filtration industry, FILTECH is well-deserved of its name. FILTECH originated in 1967 and is held every two years. It is one of the few professional filtration and separation exhibitions in Europe. FILTECH brings together the most cutting-edge technologies and products in the filtration industry. At the exhibition, you can find professional filtration solutions in the industry, covering various market fields.

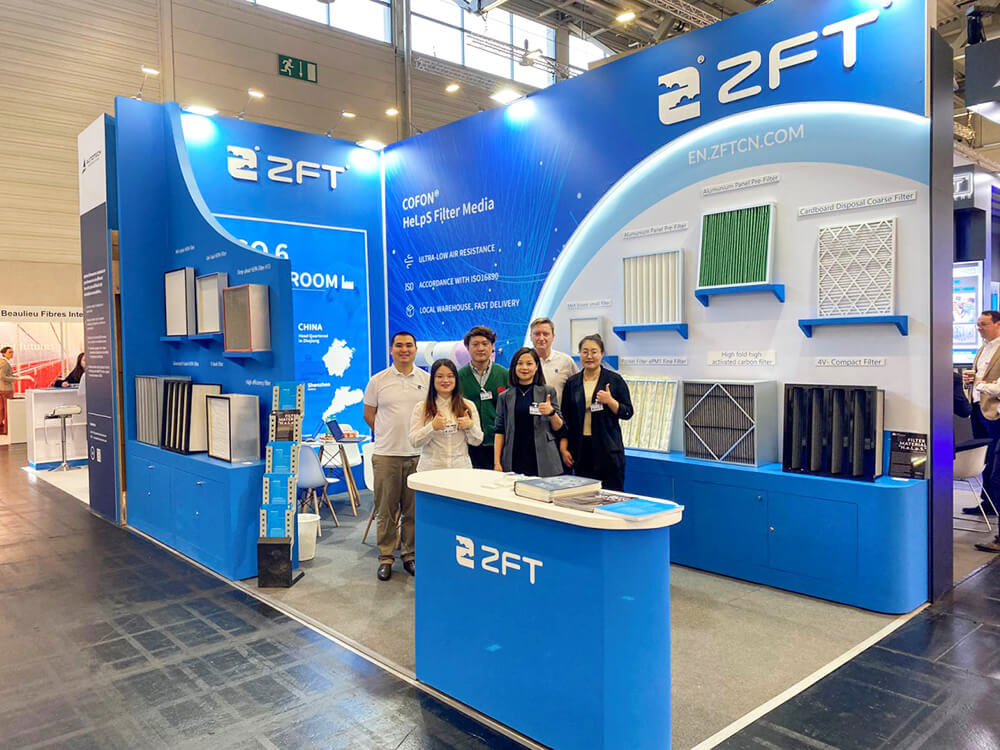

2023 FILTECH will be held as scheduled on February 14, 2023 at the Cologne International Exhibition Center in Germany, with nearly 400 exhibitors participating. ZFT is honored to participate in the event for the third time. After more than two years of technology accumulation, we met with the participants with a brand-new image and product technology, and brought a new product solution to the filtration industry, which was recognized by many people in the industry.

Air pollution can be seen everywhere, not only endangering the survival and growth of animals and plants, but also causing great harm to human health. Air governance has become an important event in the environmental protection industry. At the exhibition site, ZFT appeared in a blue overall shape, hoping to promote the environmental protection concept of blue sky and clear water.

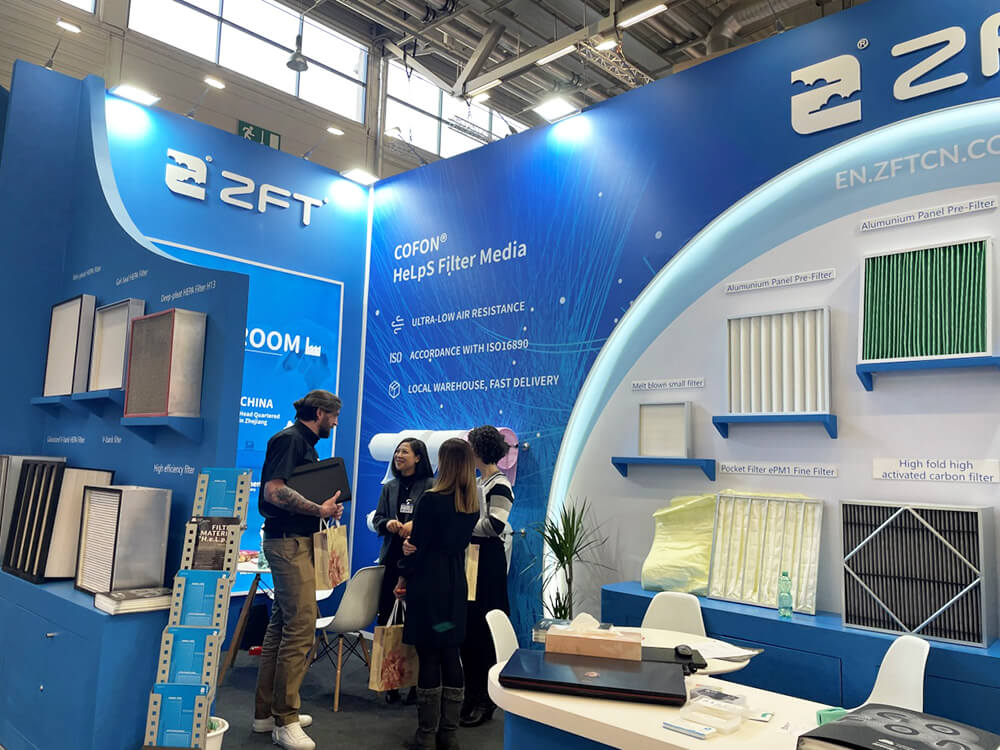

The pre-bag filter, pre-format filter, V-bank filter, medium-efficiency glass fiber filter, medium-efficiency chemical fiber filter, high-efficiency filter, liquid tank filter, HVAC filter material, etc. As the mainstream product in the filtration industry, ZFT is committed to providing professional air filtration products and services for domestic and foreign users, and injecting vitality into promoting global sustainable development, saving energy, and realizing healthy production and life.

In the field of filtration, it is an extremely difficult technology to achieve high efficiency and low resistance of the product. In order to achieve high filtration efficiency and low resistance of the filter, ZFT Co., Ltd. has devoted one year to research and development and adopted multi-layer composite technology. The resistance is 20% lower than the industry level. After team discussion, we named the product H.e.L.p.S, implying the high efficiency and low resistance of the product.

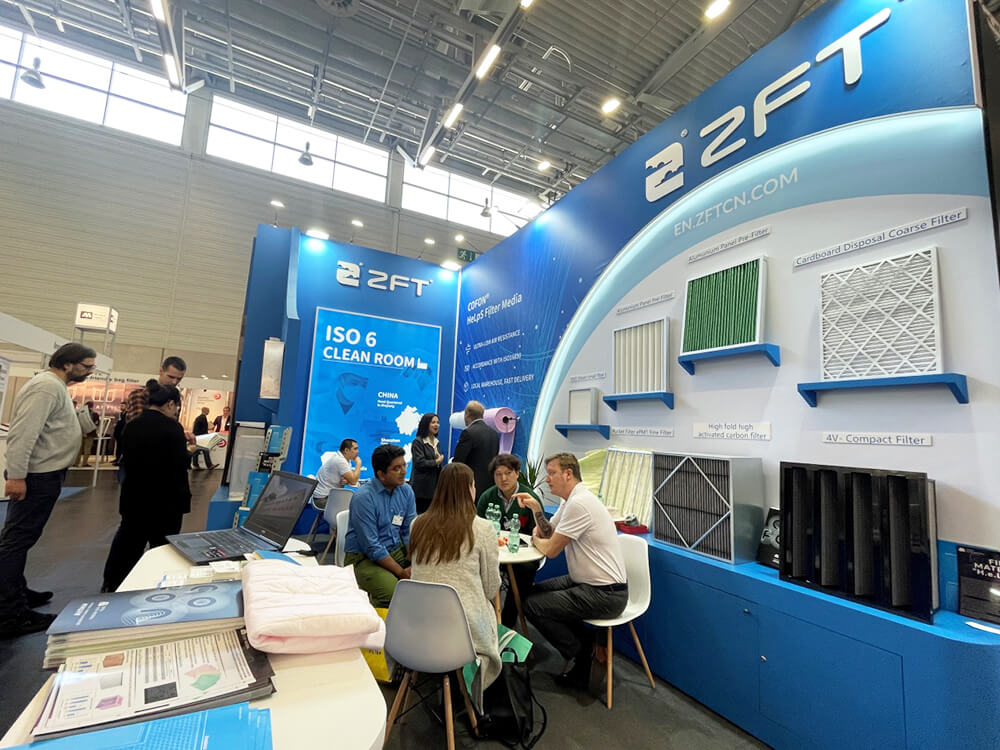

The on-site customers inquired carefully about H.e.L.p.S materials, showed strong interest, and reached many preliminary cooperation intentions.

The bag filter made of H.e.L.p.S material is light in weight and long in life. It can be used in various public buildings, industrial and agricultural ventilation and filtration systems.

Industries such as aerospace engineering, precision instrument manufacturing, semiconductors, medical and health care, bioengineering, and photovoltaic electronics have very high requirements for the manufacturing environment. Manufacturing and R&D are carried out by building clean rooms, also known as clean rooms. ZFT has low, medium and high efficiency filters, and also provides clean room filtration solutions.

We have always paid attention to the quality of products, not only from the product itself, but also have strict requirements on the production environment to build a 10,000-class clean workshop. The products are leak tested one by one according to the EN1822 standard to ensure high quality.

During the three-day exhibition, we communicated with customers from different countries and regions, and understood the different needs of customers, different industries and different product requirements. After that, we will integrate all information, further concentrate on research and development, and provide customers with high-quality products. with service.