ZFT Group 2025 Shenzhen Semiconductor Exhibition: Empowering the Future of the Industry with Clean Technology

2025-9-17

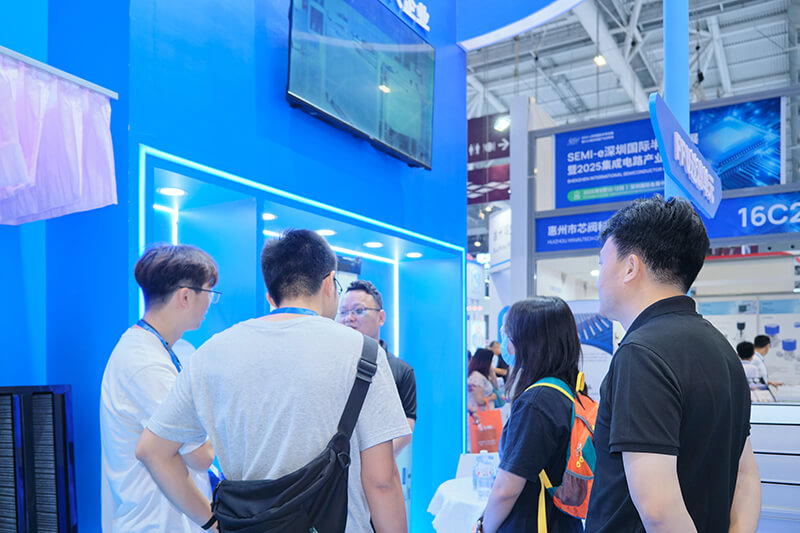

From September 10-12, 2025 , the Shenzhen International Convention and Exhibition Center (Bao'an New Hall) hosted the semiconductor industry's annual event— the Shenzhen International Semiconductor Exhibition and Integrated Circuit Industry Innovation Exhibition (SEMI-e 2025) . As a key intersection of the global semiconductor supply chain, this year's exhibition, themed "Cores for the Future, Intelligent Creation of Ecosystems," brought together over 1,000 leading domestic and international companies. The exhibition area exceeded 60,000 square meters, covering the entire supply chain ecosystem, including chip design, wafer manufacturing, advanced packaging, semiconductor equipment, and materials.

As a benchmark enterprise in the field of clean technology, ZFT Group brought its core solutions for semiconductor clean rooms to explore the future with colleagues in the industry.

Protecting semiconductor manufacturing with clean technology

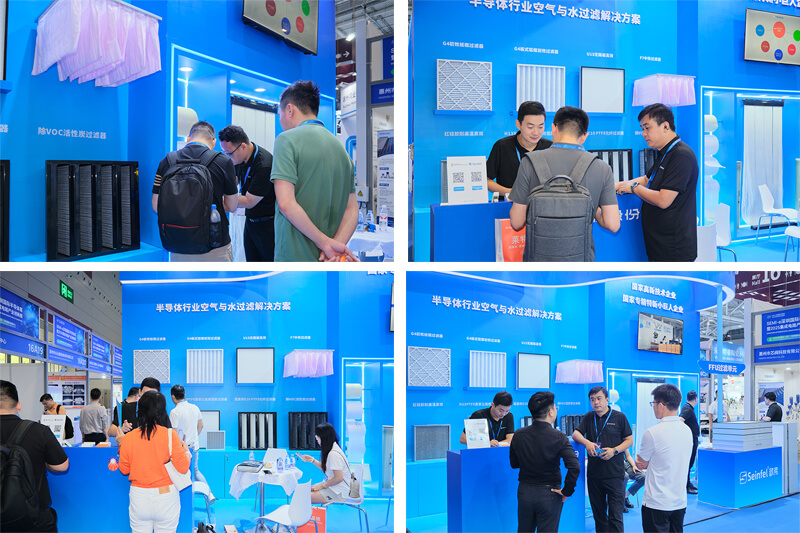

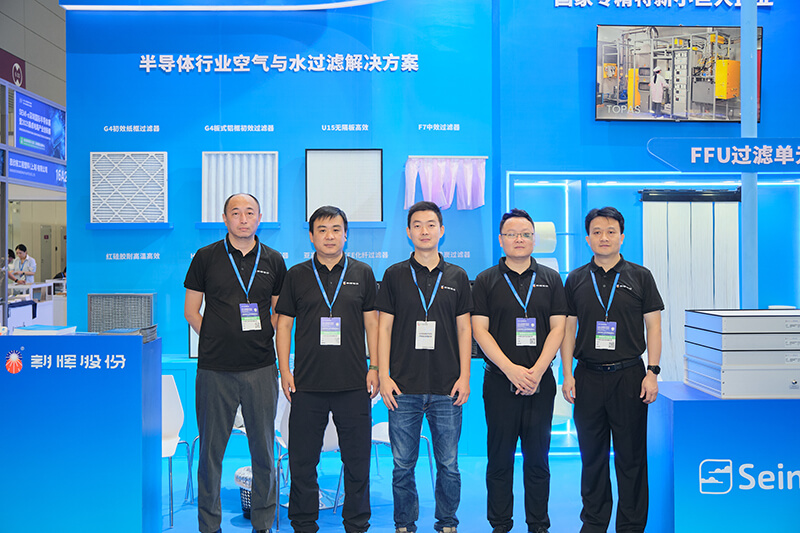

As the semiconductor industry accelerates its evolution toward high precision and high integration, a clean environment has become crucial for ensuring chip yield and performance. ZFT Group 's participation in this exhibition aims to provide semiconductor customers with comprehensive clean solutions from air purification to water treatment by showcasing its three core product lines: primary, medium, and high-efficiency filters ; FFUs (fan filter units) ; and water filtration RO membranes and ultrafiltration MBR systems .

Air purification system : In response to the stringent cleanliness requirements of wafer manufacturing, packaging and testing, Zhaohui's primary filters can intercept large particle pollutants, medium-efficiency filters further filter micron-sized particles, and high-efficiency filters (such as HEPA/ULPA) achieve an interception efficiency of more than 99.97% for 0.3μm particles, building the "last line of defense" for the dust-free workshop.

FFU unit : Flexible deployment is achieved through modular design, supporting wind speed adjustment and energy consumption optimization, adapting to different cleanliness level requirements, and helping customers reduce operation and maintenance costs.

Water treatment system : After treatment through a combination of UF ultrafiltration and RO reverse osmosis membrane technology, further deep treatment and purification through EDI (electrodeionization) or polishing mixed bed can effectively remove ions, microorganisms and organic matter in the water, meeting the ultrapure water requirements of semiconductor cleaning, etching and other processes, helping customers achieve efficient use of water resources .

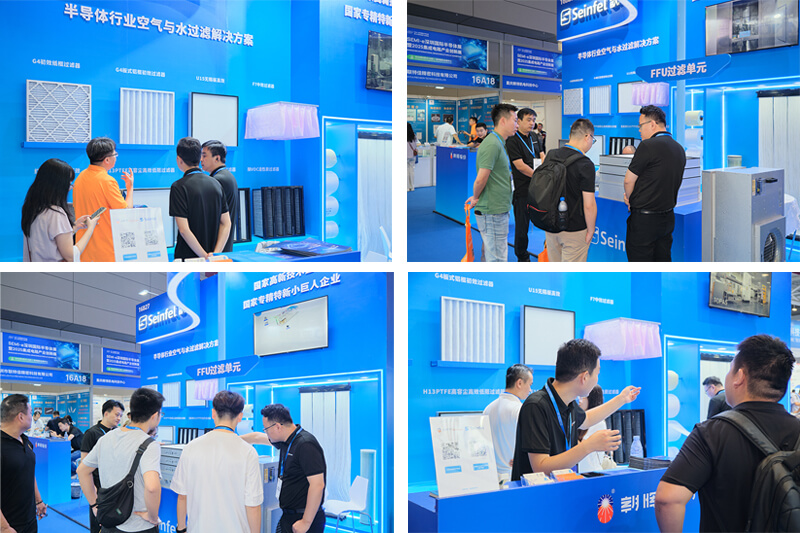

Deepen cooperation and jointly develop a new industrial ecosystem

During the exhibition, the ZFT Group team held in-depth dialogues with universities and companies such as Samsung Semiconductor , PWT China , Southwest Jiaotong University , BYD , and Fudan University , clarifying the core demands of customers and research institutions for cleanroom energy consumption optimization, water treatment system stability, and filter life extension, providing direction for the development of next-generation products .